CREATING BEAUTIFUL FLOORS

STOCKMAN’S RIDGE REPRESENTS A WHOLE NEW GENERATION OF FLOORING, ENGINEERED WITH CARE TO HONOUR THE TIMELESS BEAUTY AND ELEGANCE OF AUSTRALIA’S HARDWOOD.

In this PDF, you will find a comprehensive overview of the manufacturing process, detailing the dedication and expertise we apply so we bring you only the finest in this major development of engineered timber flooring.

1. SPECIALTY DE-STRESSED VENEER

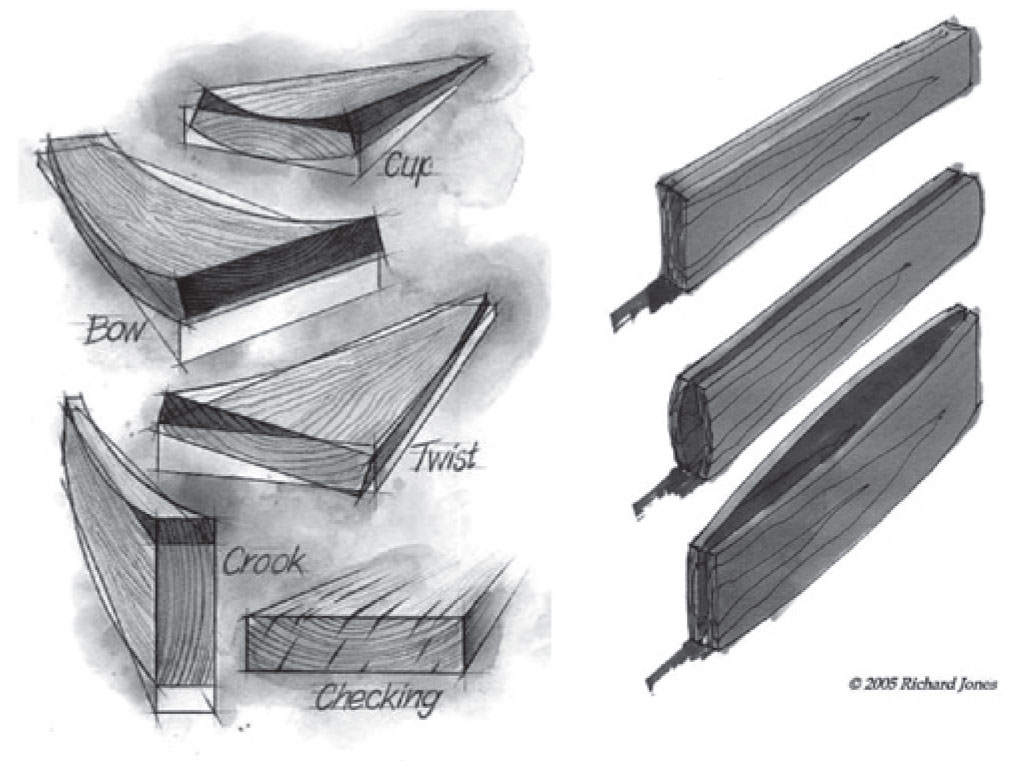

The high stability of Stockmans Ridge means less concern with checking and cupping, while our highly efficient manufacturing techniques means that one cubic meter of log can produce from between 20 and 30 times the area of a solid timber floor.

What can go wrong?

1.1 Typical issues on timber flooring surface

1.2 Internal stresses in timber

De-Stressprocessin Stockmans Ridge Veneer

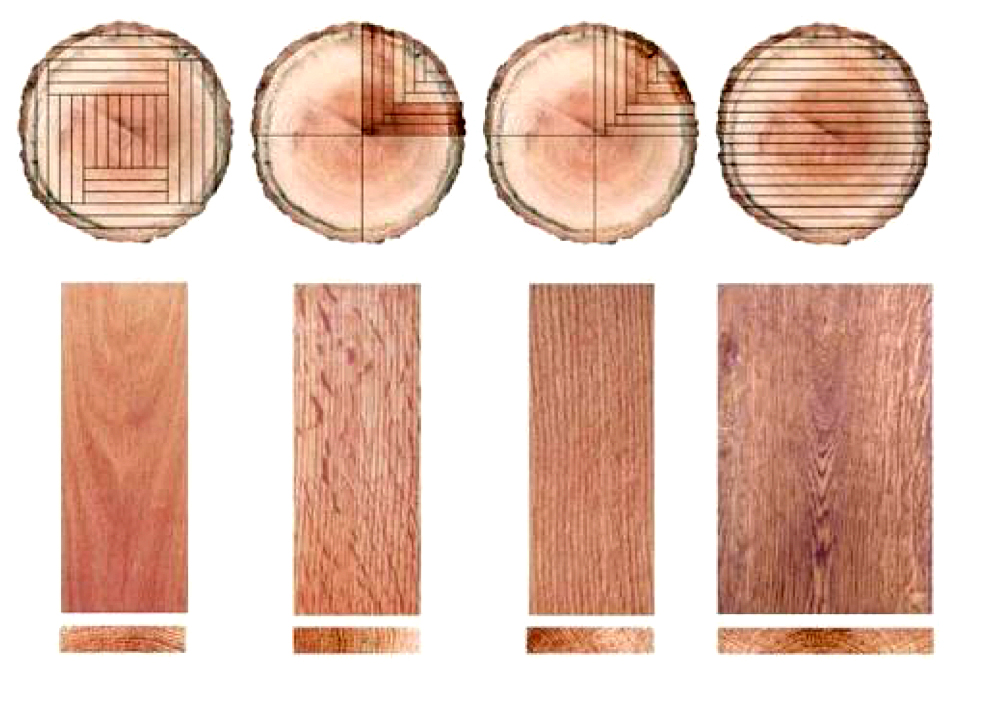

1.4 Veneerprocessandgrading

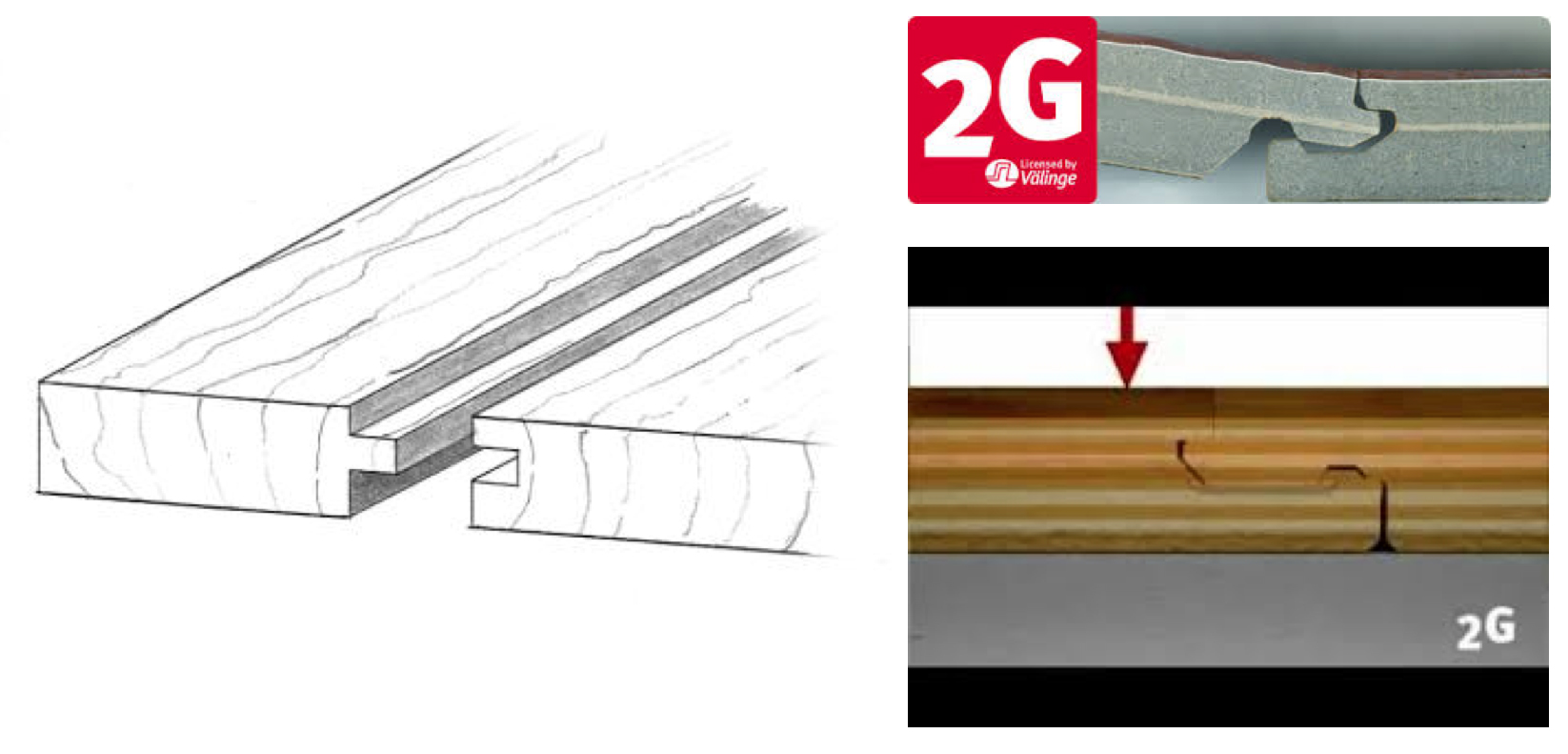

1.5 Veneerstabilitytestinhumiditychamber

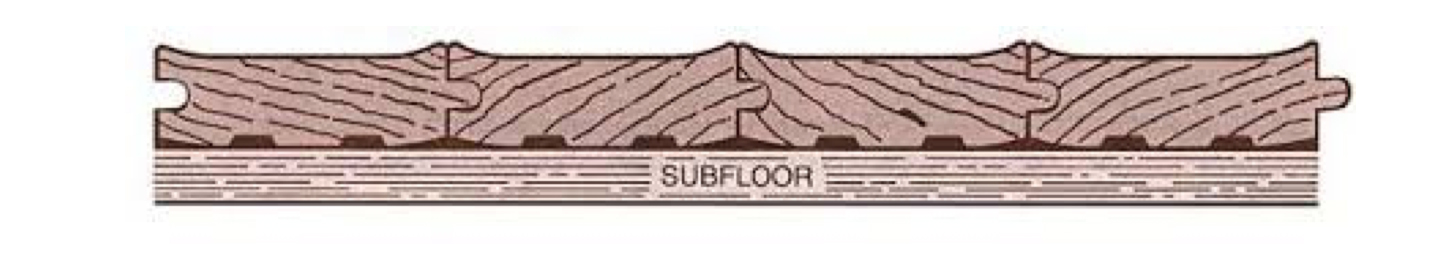

2. SPECIALLY DESIGNED STRUCTURE

2.1 Structuralbalance

Cross laminated substrate by plantation Eucalyptus/ Back veneer in high density compatible to Australian hardwoods.

2.2 Structuralimbalance

A typical issue in the market

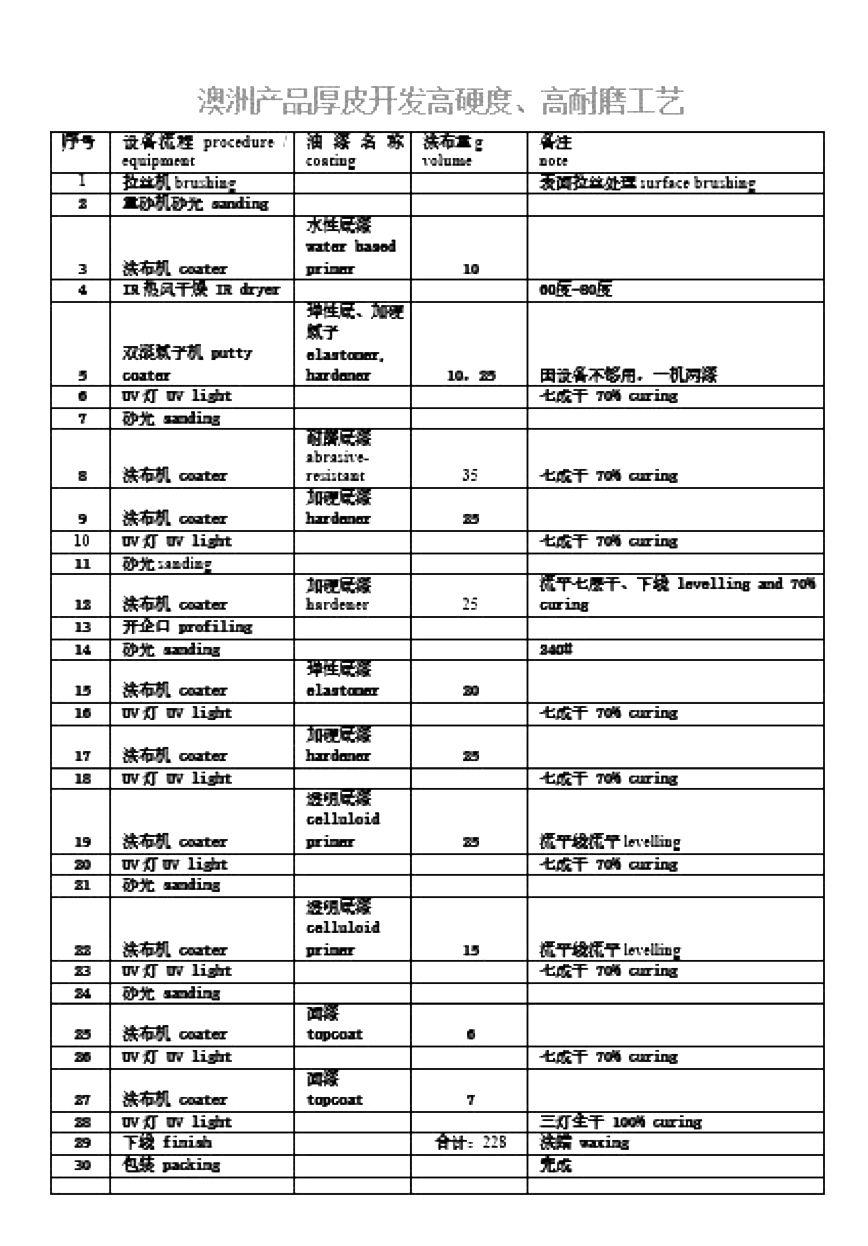

3. TAILORED PLATINUM COATING PROCEDURE

- For greater durability, Stockmans Ridge flooring utilises an acrylic coating

- 14 coats comprehensive mix for enhanced performance against wear and tear

- Clear coating for true timber grain and color in appearance

- Developed and backed up by PPG

3.1 Coating Procedure for Stockmans Ridge

A special mix of elastomer, hardener and abrasive resistant primer for extra wear protection on top of veneer

Coating Line

abrasive and scratch resistance

De-Stressprocessin Stockmans Ridge Veneer

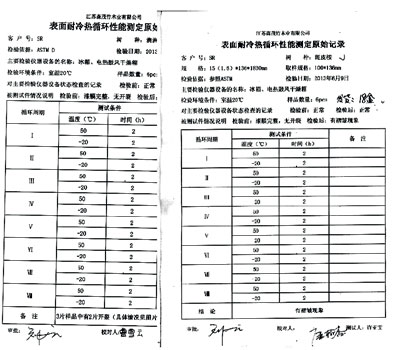

3.2 Taber Test

Test results on typical normal solid wood 600-800

rotations; laminate flooring 4000-8000 rotations

4. 186MM TRUE TIMBER GRAIN

- Timber grain and color best honored

- Wide plank properly showing beauty and elegance of Australian hardwood

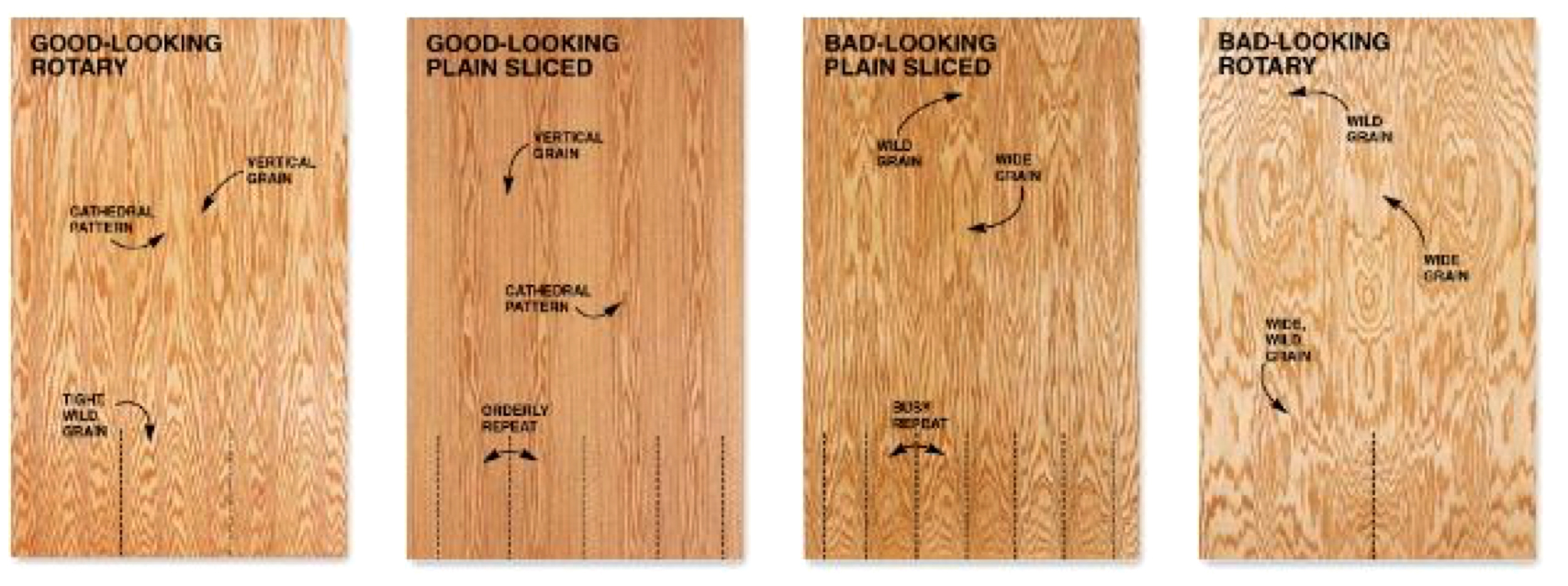

4.1 Timber grain in 186mm wide – Wider boards, better appearance

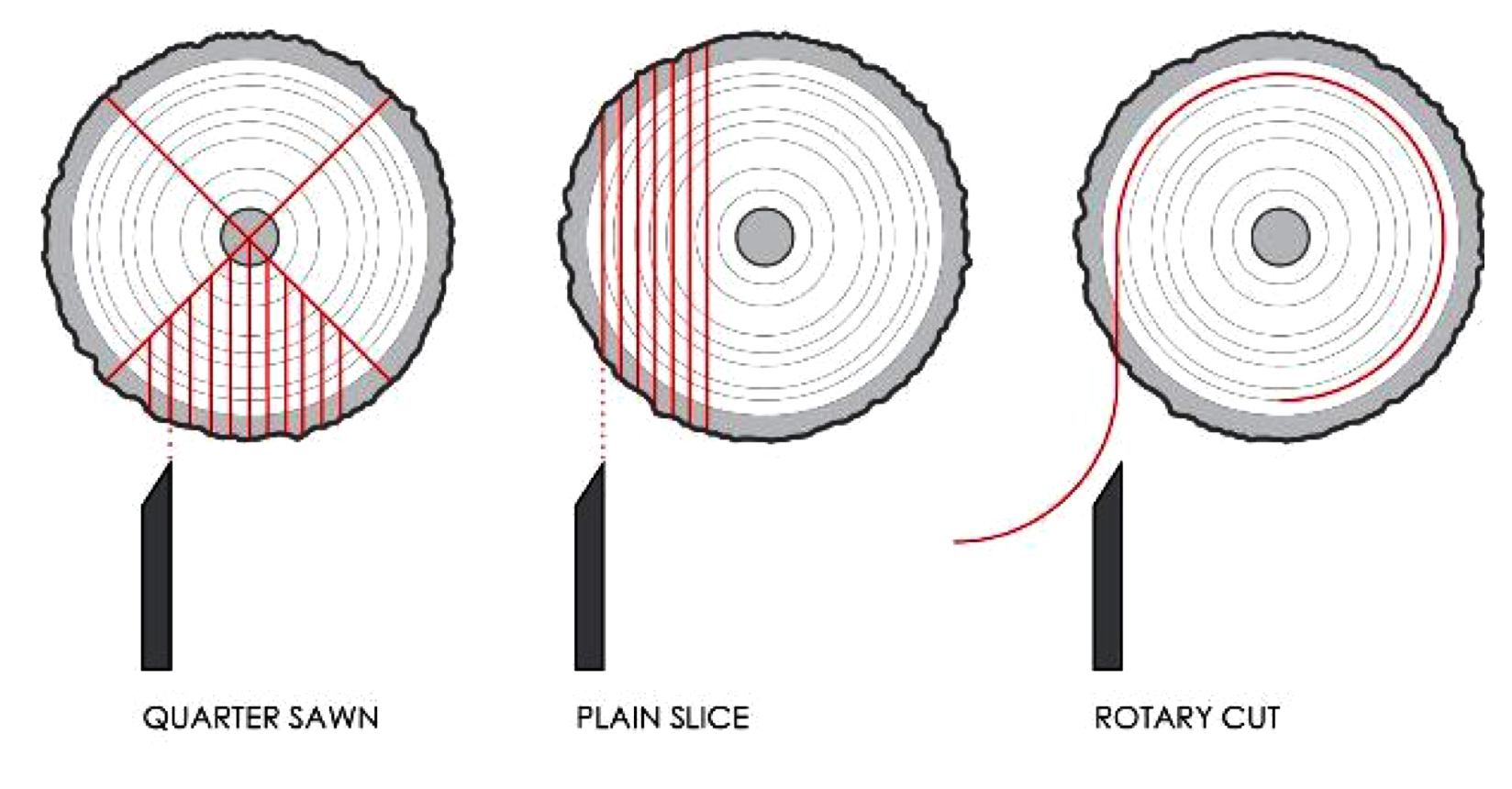

4.2 Grain from Rotary Cutting

Proper timber grain cut from tangential the growth rings.

Rotary cutting along the growth rings won’t produce proper timber grain

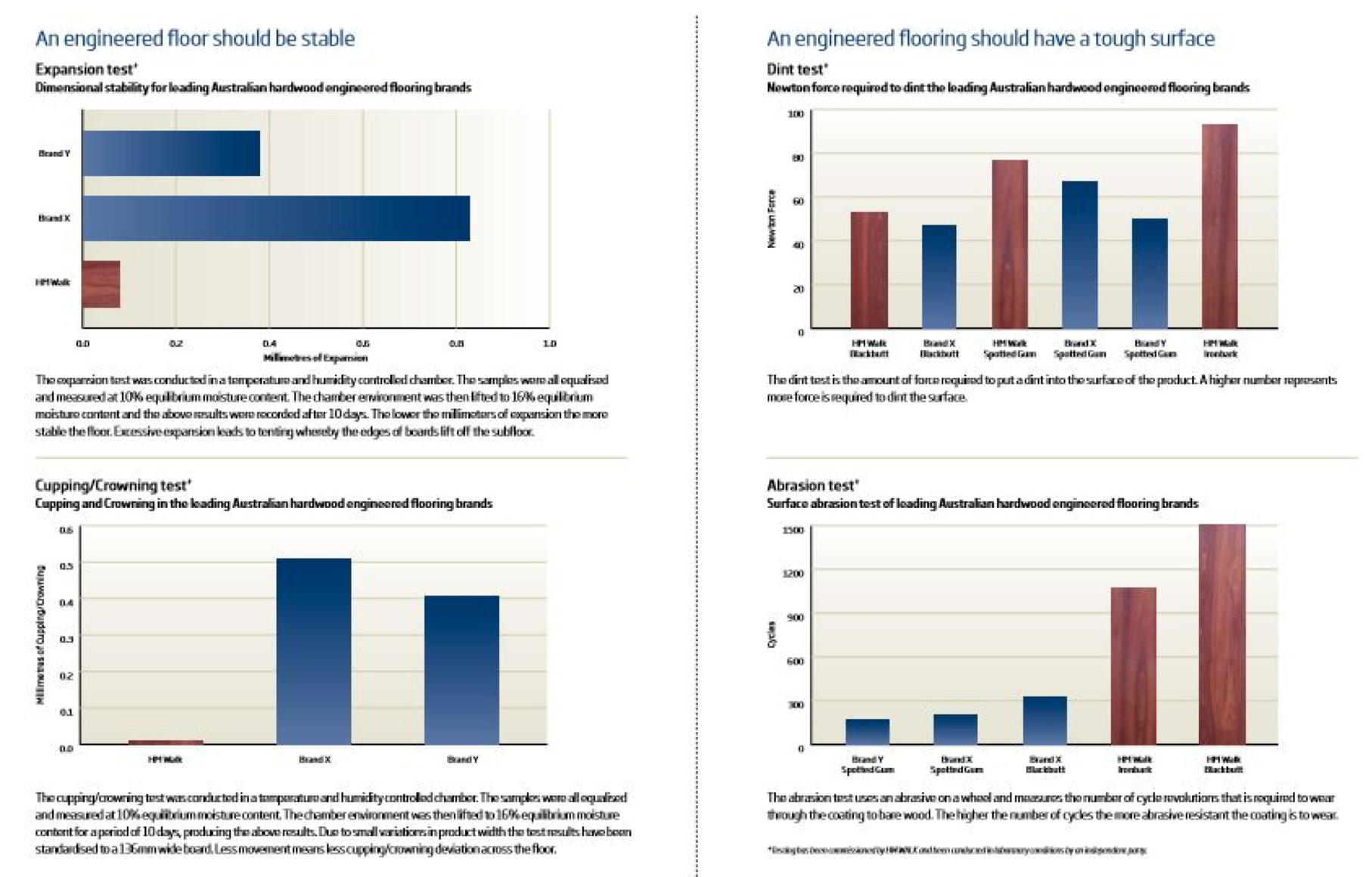

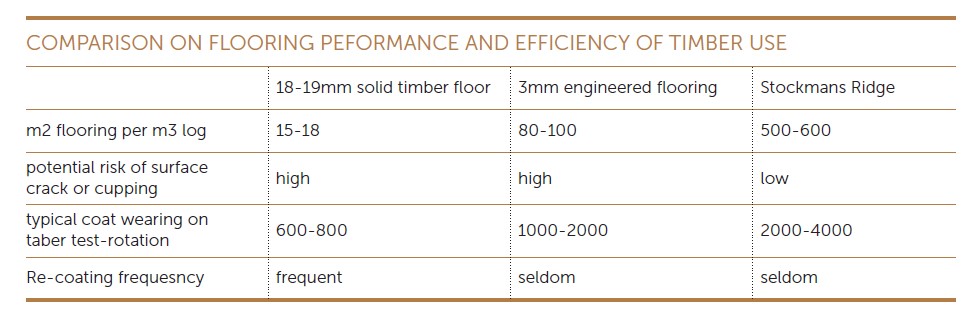

5. COMPARISONS WITH OTHER TYPE FLOOR

- Less expansion and contract

- Less cupping and crowning

- More resistance against dentation, scratch and abrasive

- Easier in care and maintenance, less chance for rejuvenation

- No need of re-sanding

- » Higher recovery in timber use and more floor covering areaLess cupping and crowning

5.1 Performance Comparisons

5.2 High Efficiency in Timber Use – environmental benefits

6. REFRESH COATING

- Less chance for movement in timber veneer, Stockmans Ridge stays flat in surface all the time

- No drum sanding needed

- Coating system provides extra wear and tear resistance

- Buff sanding only needed to remove existing coating before rejuvenation

6.1 Re-sanding or Refresh coating

Why re-sanding?

- Surface faults – cupping/checking/warping. Drum sanding needed to render the floor surface flat before coating.

- Wear and tear

This is not applicable for Stockman’s Ridge

-

Refresh Coating

- Rejuvenation on the wear and tear

- Buff Sanding only to remove the coat before re-coating

Stockmans Ridge will stay flat on surface in lifetime, no need of drum sanding at any time.

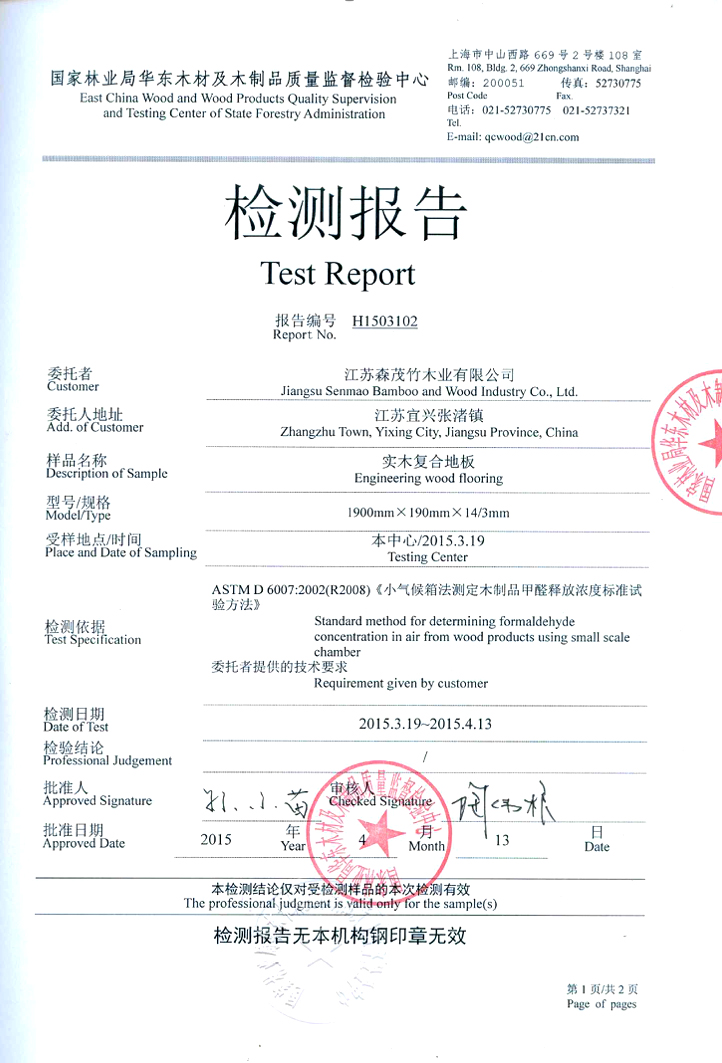

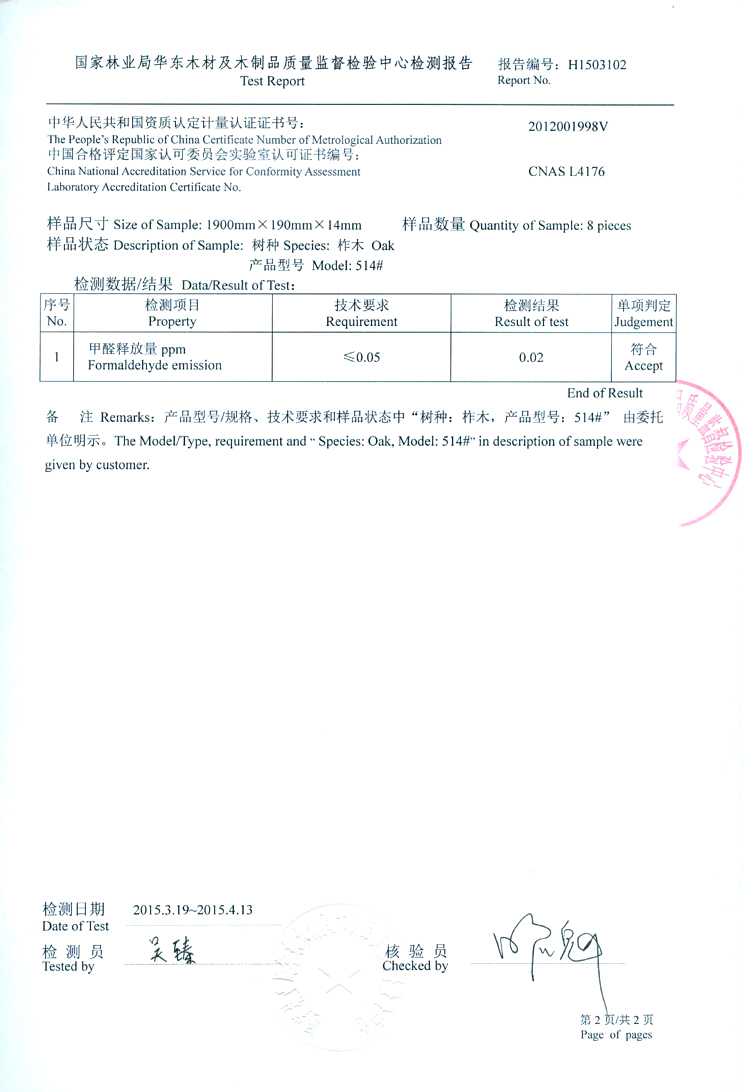

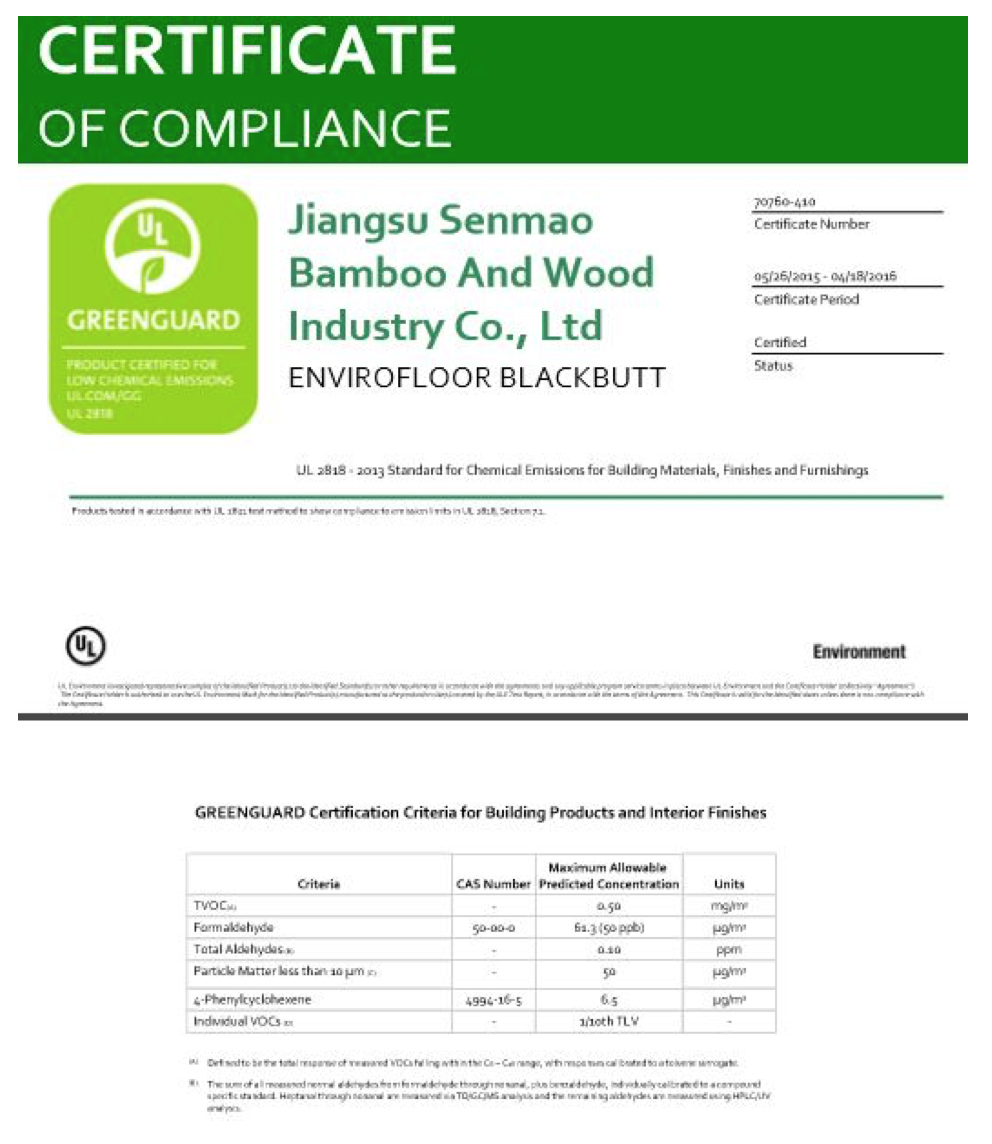

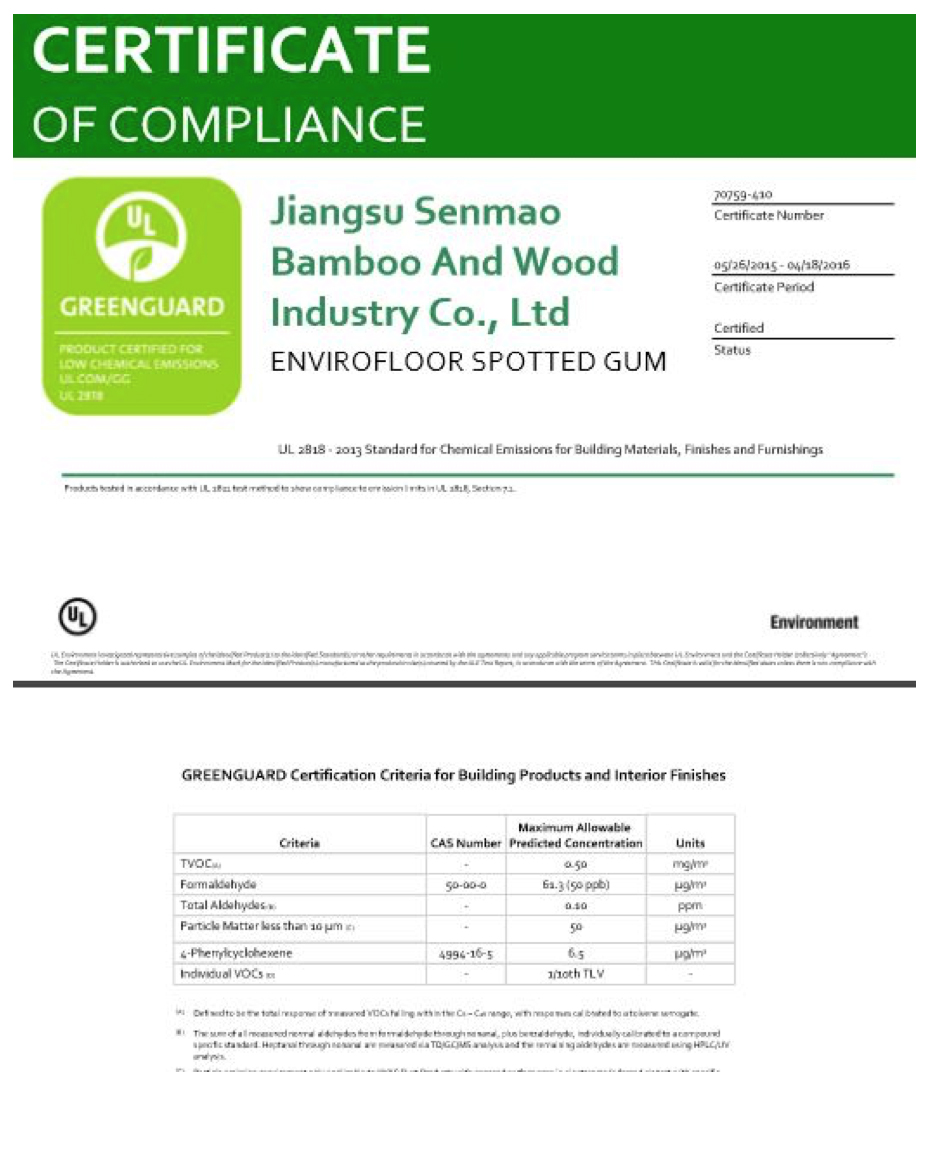

7. CHEMICAL EMISSION

- CARB test to American standard ASTM D6007-2002 for formaldehyde concentration in air

- GREENGUARD certification

- floorscore certification

ASTM D6007-2002 testing formaldehyde concentration in air

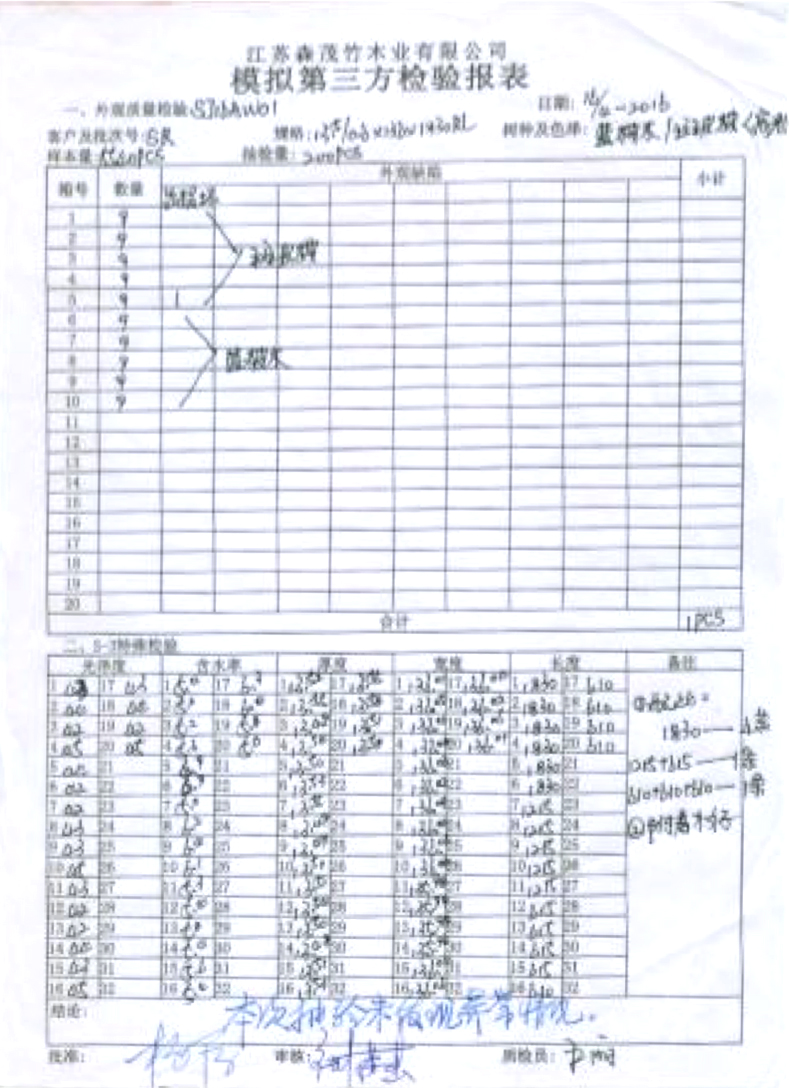

8 QUALITY CONTROL

- Procedure in place to monitor and control the quality of each step in production progress

and every material putting into use - Full facility testing strength, surface wearing resistance and chemical emission

- Batch release test report

9. CHAIN OF CUSTODY

- FSC certification

10. VÄLINGE LOCKING SYSTEM